Choosing the right Sandwich Insulation Board for your project can be challenging. Experts stress the importance of selecting the appropriate materials. John Smith, a renowned specialist in insulation technology, once said, "The right choice can significantly impact energy efficiency."

The market offers various options, each with unique properties. For instance, thickness and thermal performance can vary widely. It’s crucial to evaluate your specific needs against the board's specifications. Some boards might even struggle to meet energy standards.

Reflecting on your project’s requirements is essential. Consider factors such as location, climate, and budget. The perfect sandwich insulation board exists, but it may require careful research to find it. Don’t overlook the importance of seeking expert advice.

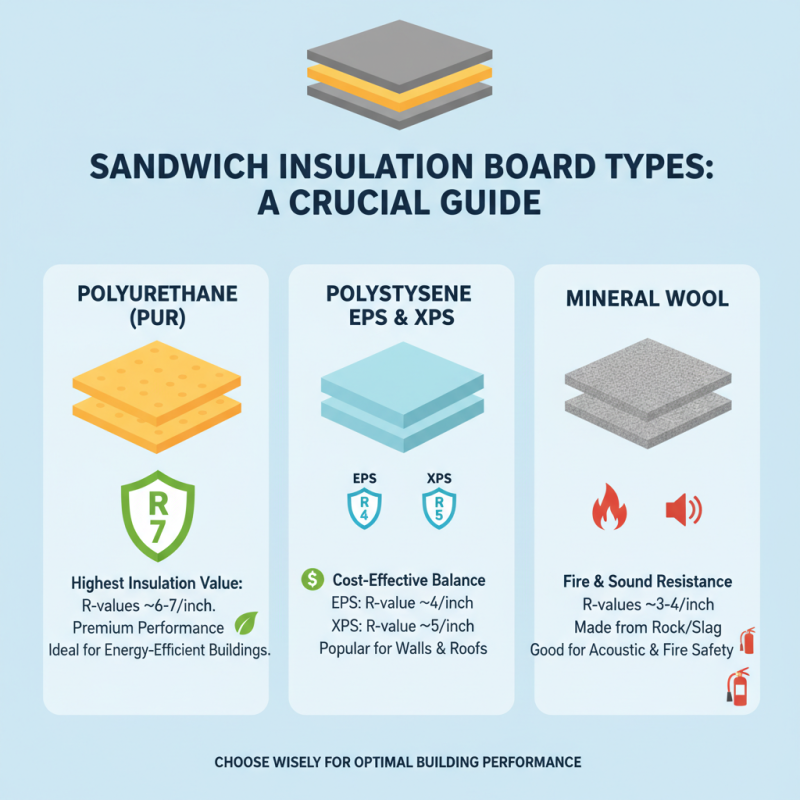

When selecting a sandwich insulation board, understanding the types available is crucial. Various materials dominate the market, including polyurethane (PUR), polystyrene (EPS), and mineral wool. According to industry reports, polyurethane boards offer the best insulation values, with R-values around 6-7 per inch. This high performance makes PUR ideal for energy-efficient buildings. Polystyrene boards, both expanded (EPS) and extruded (XPS), are popular for their balance of cost and insulation. EPS typically has an R-value of 4 per inch, while XPS reaches about 5.

One tip to consider is the environment and application. Mineral wool boards, while not as efficient, provide fire resistance and soundproofing, making them suitable for specific projects. It's essential to analyze your project's needs thoroughly. Insulation boards can be heavy, which may affect handling and installation.

Choosing the right sandwich insulation board also involves performance under pressure. Compression strength varies widely; PUR often outperforms others here. Be cautious of weight limits in your building design. This is an area where miscalculations can lead to costly rebuilding or adjustments. Always verify specifications from multiple sources. Inspect the boards for consistency and imperfections before purchase. Quality may vary, and not all boards perform as advertised.

Selecting the right insulation thickness for your sandwich insulation board is crucial for energy efficiency. According to the U.S. Department of Energy, optimal insulation thickness can significantly reduce heating costs by up to 40%. This highlights the need to choose wisely.

When considering insulation thickness, local climate conditions play a pivotal role. In colder areas, thicker insulation helps retain heat. Conversely, in milder climates, it may not be necessary to go beyond minimal thickness. The choice should reflect the environment in which the structure is located.

Another important aspect is the R-value, which measures thermal resistance. Higher R-values indicate better insulation. Studies suggest that every inch of thickness can increase the R-value by approximately 3. You might find that a thicker board offers diminishing returns in certain settings. Balancing thickness with cost and performance requires careful thought and analysis.

This chart illustrates key factors to consider when selecting insulation thickness for sandwich boards, including R-Value, cost, weight, and thickness. Proper selection ensures optimal energy efficiency and cost-effectiveness in your projects.

When choosing a sandwich insulation board, understanding the R-value is crucial. The R-value measures an insulation material's resistance to heat flow. Higher R-values indicate better insulation performance. The Department of Energy states that insulation can save up to 30% on heating and cooling costs. In colder climates, an R-value of 30 is recommended for attics. However, achieving this can be a challenge with traditional materials.

Insulation boards come in different types, affecting their R-values. Polystyrene boards typically offer an R-value of 3.6 to 4.2 per inch. In contrast, polyurethane boards can provide up to 6.5 per inch. The choice ultimately depends on the specific project needs and budget. Factors like moisture resistance and durability also play a role.

One must reflect on potential downsides. Not all high R-value materials are suitable for every application. Some may not perform well in high humidity. Additionally, installation is key. Poor installation can reduce effectiveness, regardless of the R-value. Always consider the whole insulation strategy, not just the board's R-value.

When selecting sandwich insulation boards, durability is a key factor. Materials should withstand wear and tear over time. Consider the local climate. Extreme temperatures may influence the board's longevity. Look for insulation with good resistance to moisture, too. Water damage can lead to mold and decay, impacting both insulation and structural integrity.

Evaluate the environmental impact of your chosen materials. Some boards may be made from sustainable resources. Recycled content can lower your carbon footprint. However, not all eco-friendly options perform equally in insulation effectiveness. Be prepared for compromises. Assess the balance between durability and environmental friendliness. Some may lack the strength needed for specific projects. This is a critical reflection point, especially when aiming for long-lasting construction and minimal ecological effects. Choosing wisely hinges on weighing these factors carefully.

| Material Type | Durability Rating (Years) | Environmental Impact (Low/Medium/High) | R-Value (per inch) | Cost per Square Foot (USD) |

|---|---|---|---|---|

| Polyurethane Foam | 25 | Medium | 6.0 | $1.50 |

| EPS (Expanded Polystyrene) | 20 | High | 4.0 | $0.75 |

| XPS (Extruded Polystyrene) | 30 | Medium | 5.0 | $1.10 |

| Mineral Wool | 50 | Low | 3.0 | $1.20 |

| Polyisocyanurate | 25 | Medium | 6.5 | $1.75 |

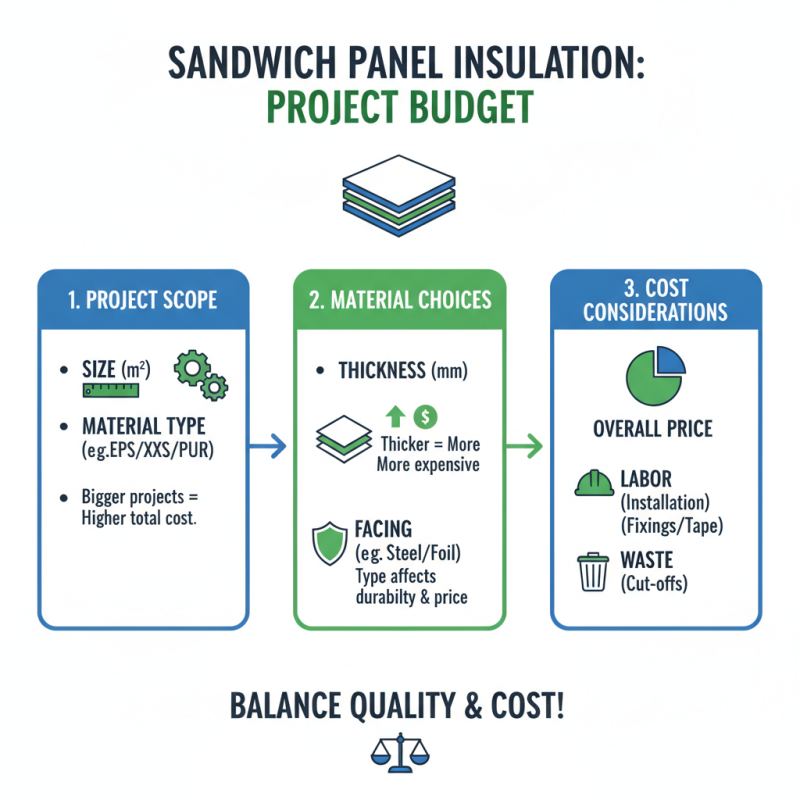

When budgeting for a sandwich insulation board project, costs can quickly pile up. Start by assessing the size of your project and the materials needed. Each choice impacts the overall price. For instance, thicker boards typically offer better insulation but may increase expenses. It's essential to balance quality and cost effectively.

Labor costs can also be a significant factor. Hiring specialized contractors can be pricey. You might consider a DIY approach if you're handy. However, this comes with its risks. Mistakes in installation can lead to additional expenses later. Have a contingency budget for unexpected costs.

Also, don't forget about long-term savings. Higher upfront costs may lead to more efficient energy use. This trade-off needs careful thought. Evaluate your priorities. It’s easy to fixate on initial costs while neglecting potential benefits. Always ask yourself: What is the true value of my investment?